Tel: +8653185996661

Mob: +8613789821291(Wechat)

Add: LuoER High-tech Development Zone, Dangjia Town, Shizhong District,

Jinan City, Shandong Province

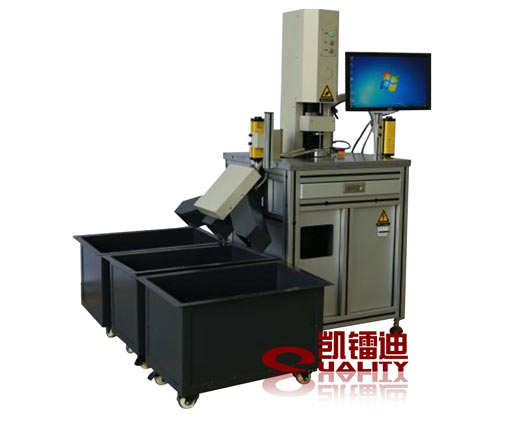

This machine positioning for the flexible load sorting, especially suitable for medium spring batch, high precision spring testing, spring varieties and frequent replacement, and for the spring shape is not suitable for the use of vibrating screen feeding tube, or shaped spring. The machine is complementary to the conventional sorting machine for load on the test spring batch, type, shape and other requirements. There are several cases to use the machine more convenient and efficient.

Features

Generally, it is difficult to achieve automatic feeding of vibrating screen, can use the machine, or with manual feeding or with automatic feeding(according the springs)

This machine is suitable for the mode of variety, small batch, frequent replacement of varieties, because of the convenience of variety replacement and parameter adjustment, the production efficiency is greatly improved; different from the conventional sorting machine on the requirements of the auxiliary tooling

Main function and advantages

1 This sorting machine has the control system of the whole process from feeding, testing, judging, automatic exit, classification function, safety, protection and so on. Through customized automatic feeding, the automatic sorting of the whole process can be realized, or it can only manually feeding, the other actions are all automatically controlled. There are five spring outlets.

2 High test efficiency, up to 25 pieces/minute

3 Two test mode "load at a determined heigth" and "load at a determined deformation"

4 Automatic zero setting function can be done

5 The system provides reliable security protection measures

6 The schemes are set by parameters that is easy to be set, easy to be called and save the results

7 The test data can be directly exported to Excel spreadsheet, and it is convenient and fast to print and store the test data

8 own patent

Main technical parameters

| NO. | Project name | Parameters and indexes | |||

| 1 | Max load capacity (one loadcell) | 200 | 500 | 2000 | 5000 |

| 2 | measurement range of load | 5%-100% of full scale | |||

| 3 | Minimum resolution of load | 0.01N | |||

| 4 | Minimum resolution of displacement | 0.001mm | |||

| 5 | relative error of load indicator | ≤ ±0.5 % | |||

| 6 | relative error of load indicator repeatability | ≤ 0.5 % | |||

| 7 | Maximum sorting speed | 25 /min | |||

| 8 | outlets | customizable | |||

| 9 | Motor power | 1kw | |||

| 10 | Supply voltage | Single phase 220V±10% 50Hz | |||

| 11 | Net weight | ||||

| 12 | Gross weight | ||||